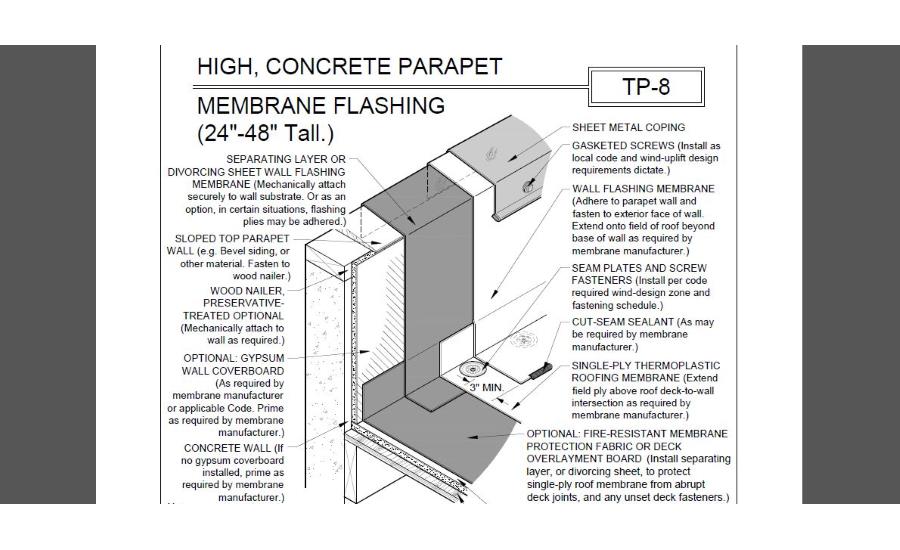

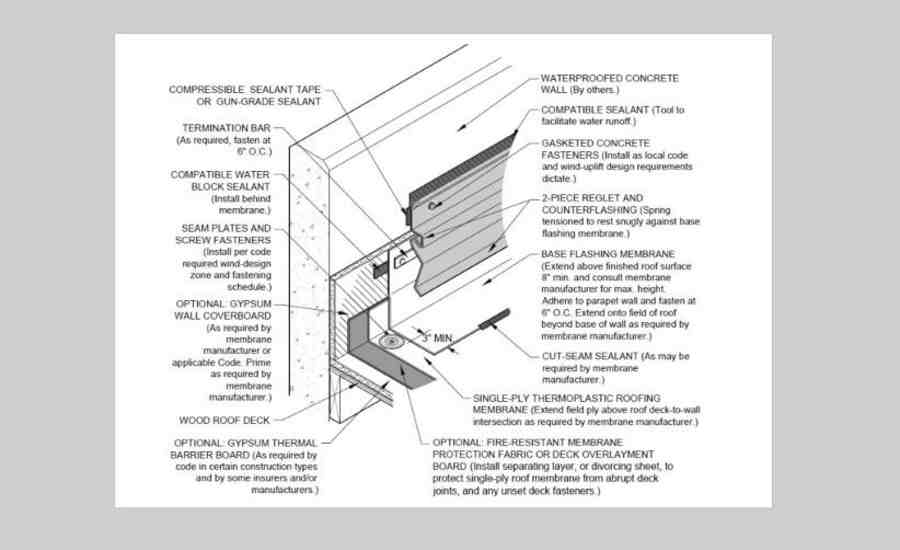

Roofing Detail High, Concrete Parapet Membrane Flashing 20180724 Building Enclosure

These transition points, where the flat part of the roofing system is tied into the parapet wall, are potentially vulnerable areas for water intrusion. Following the requirements for proper flashing can help ensure that the roof system offers better protection. How do you install flashing on the wall and roof?

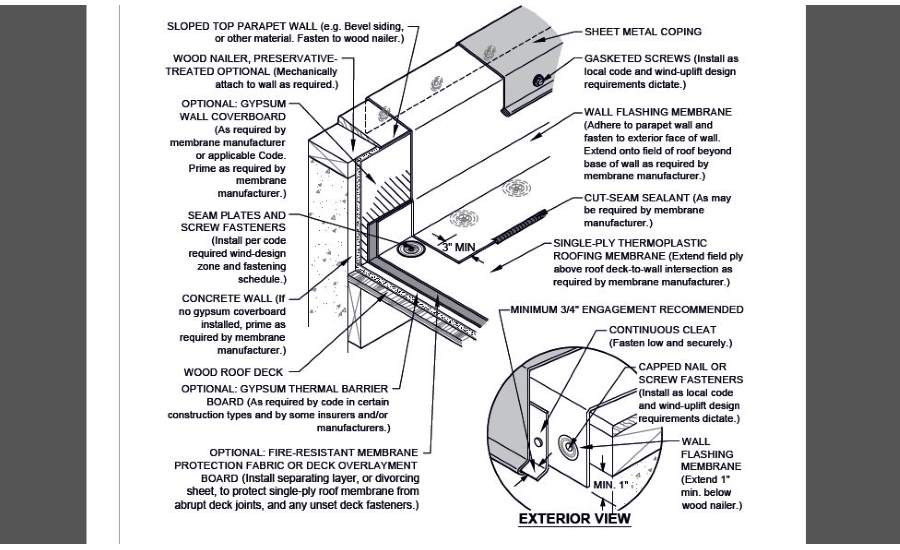

Low, WoodFramed Parapet Wall Flashing Building Enclosure

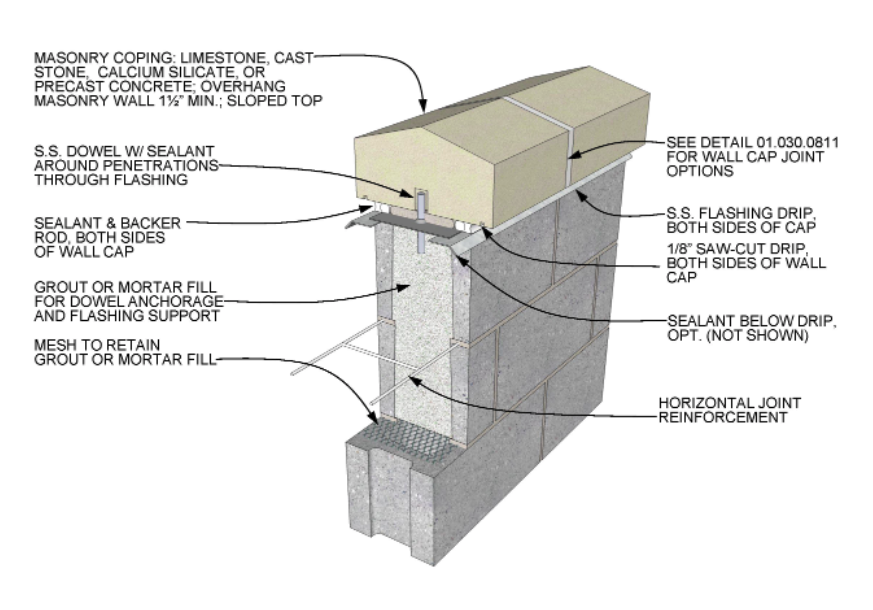

Some of the more common ways I have seen the ends of copings detailed include the following: 1) the coping terminates horizontally at or near the surface of the wall cladding; 2) the coping extends into the wall cladding (for example, masonry or EIFS) without an upturned leg and integral side flanges; and 3) the coping terminates within the wall.

WickRight makes passive vents and vented flashings to install on parapet walls and and flat

August 7, 2018. This detail is intended to be used where wall heights are greater than 24 inches above roof surface. The profile of specific components, their configuration or sequencing, can vary with the roof system, climatic differences, and regional or area practices. Dimensions as shown are recommended minimums and are intended to be.

Parapet Flashing Prestige Industrial Roofing Supplies

Parapet flashing made from sheet metal or copper and fabricated for a particular thickness of wall may be shipped to the job site in sections. Attaching flashing to a parapet wall requires basic sheet metal tools and knowledge of sheet metal or copper soldering.

Parapet Wall 10 Types Of Parapet Wall & Applications Civiconcepts

Types of Parapet Walls By Design Style Embattled Plain Perforated Paneled By Shape Flat Sloped Stepped Curved Common Uses of Parapet Walls Aesthetic Value Privacy Safety Protection From The Elements & Water Management Keep things off the roof Debris Driving rains and water infiltration Breaking up winds Fire protection Parapet Wall Construction

Parapet Flashing/Coping InterNACHI Inspection Narrative Library

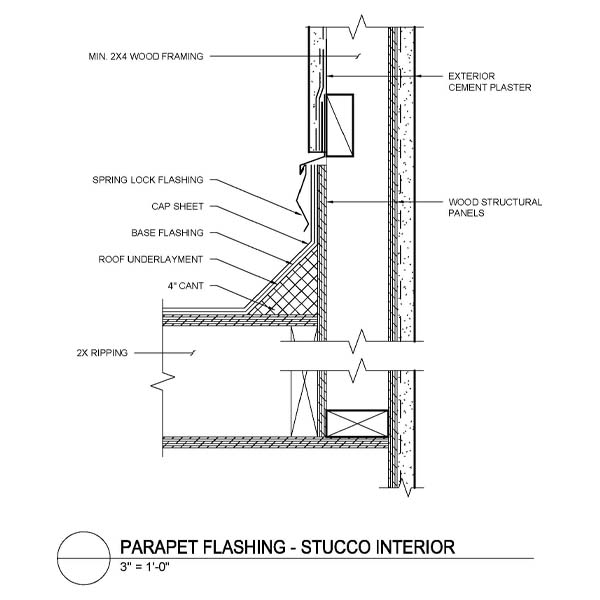

1. Height of roofing at wall: minimum of 12" to top of parapet. Do not lap TPO over top of parapet unless required by unique construction conditions. 2. Top of parapet, below cap, to be sealed with fluid applied flashing. 3. Venting in wood framed parapets: Provide venting to each wall cavity.

Roof flashings BRANZ Build

Parapet - Top Parapet-to-sheet Connection Wall Flashing Mid-Wall Connections Internal Corner - Trim Internal Corner - Moulding External Corner - Trim External Corner - Moulding Wall to Eaves/Soffit Fascia Purlin

Parapet Wall Flashing Inspection Gallery InterNACHI®

9.2B. Vertical Wall Flashing. This detail shows a flashing condition at a vertical wall or parapet. The roofing squares are locked into a 20 oz. copper base flashing, which extends at least 8" up the wall. The counterflashing laps the base flashing a minimum of 3". Download CAD File

Wall flashing Chicago, masonry flashing, lintel flashing Best Brickmasters

An installation overview showing a Parapet Wall Flashing with Counterflashing detail. This is for EverGuard TPO/PVC Single-Ply Roofing Systems. Learn more ab.

Parapet wall rebuilding in Chicago Joseph James Construction Inc. Masonry, Chimney repair

On roofs with short parapet walls, positive roof drainage must be provided. The water level on the roof must not reach any point where the the roofing membrane terminates or has been punctured, such as at cleats. 9.3A. Typical Copper Coping The detail illustrates a copper cap flashing installed over a masonry wall.

Parapet Wall Coping Cap Copper, Aluminum, Radius and More

Install a new adhesive membrane (ice and water protector) and metal step or continuous flashing that is properly integrated into the weather-resistant barrier and wall and roof coverings to provide continuous water, air, vapor, and thermal control layers on the walls and roof.

metal flashing and siding on a parapet YouTube

Low, Wood-Framed Parapet Wall Flashing. This detail is intended to be used where wall heights are 24 inches or less above roof surface. The profile of specific components, their configuration or sequencing, can vary with the roof system, climatic differences, and regional or area practices. Dimensions as shown are recommended minimums and are.

Parapet Flashing Stucco Both Sides WoodWorks Wood Products Council

Adhere membrane wall flashing to parapet wall and attach at exterior face per code wind-design fastening schedule. Continuous cleats are recommended when flashing face dimension exceeds 3 inches and in areas deemed a high-wind zone as categorized by local building code.

Detail Low, Concrete Parapet Wall Flashing 20170620 Building Enclosure

The snap coping offers a complete finish to any parapet wall. The system utilizes 16-gauge cleat segments spaced at 5' - 0" centers. EPDM TPO PVC ModBit Share:

Detail Concrete Parapet & HighWall Flashing 20170203 Building Enclosure

Exterior Wall Flashing Flashing is very important and is generally repeated in both the wall (IBC 1404.4) and roof provisions of the code. The IBC includes the principle that "flashing shall be installed… to prevent moisture from entering the wall or to redirect that moisture to the exterior."

Burwood Apron and parapet wall flashing installation

General: For an excellent explanation of the function of parapet wall coping, see "Moisture Management of Parapet Walls" on the website of MTI/Masonry Technology, Inc. 4. Building Codes : " R903.2 Flashing " and " R903.3 Coping " from the 2021 International Residential Code and " 1503.2 Flashing " and " 1503.3 Coping " from.